Glossary

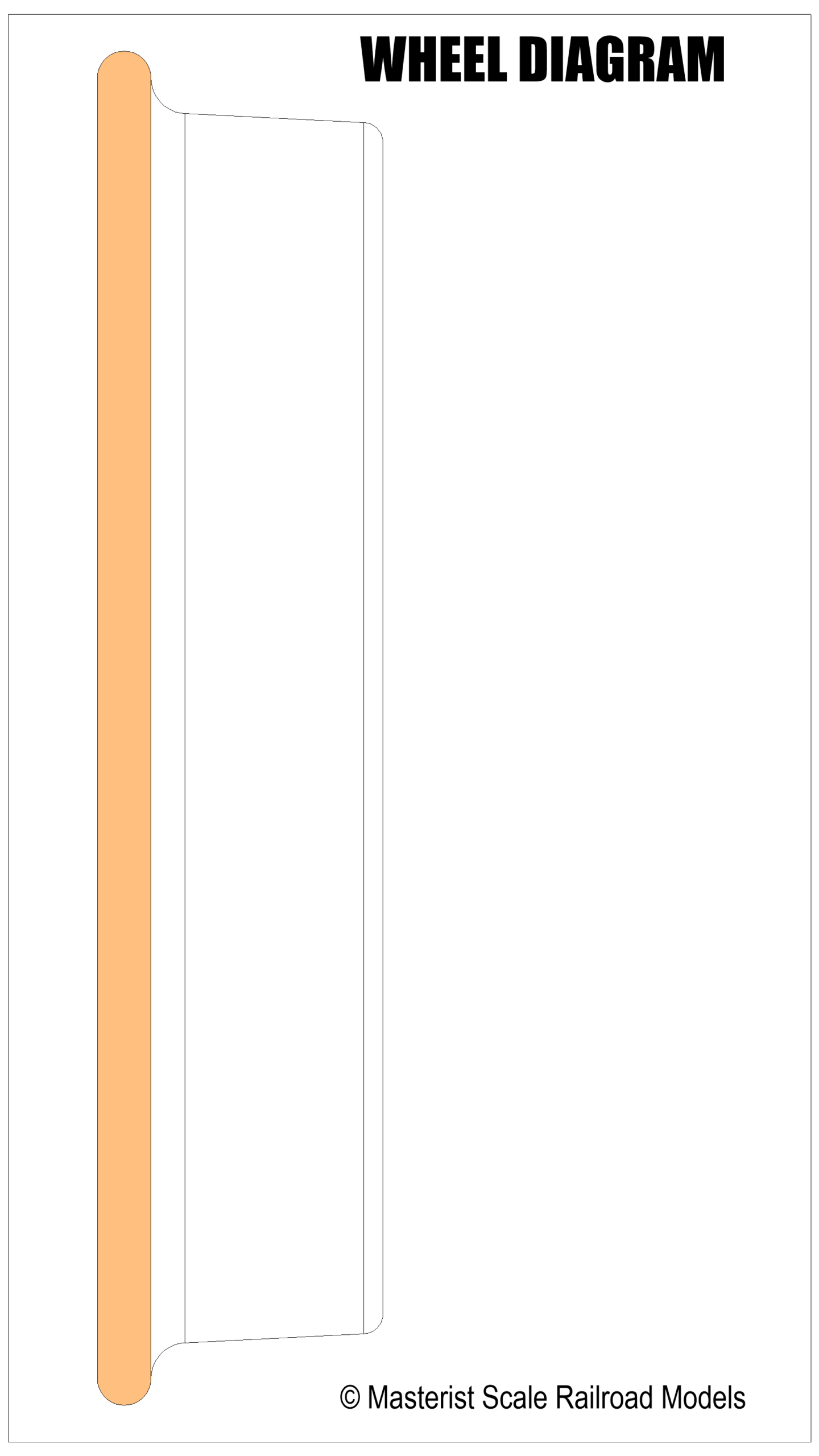

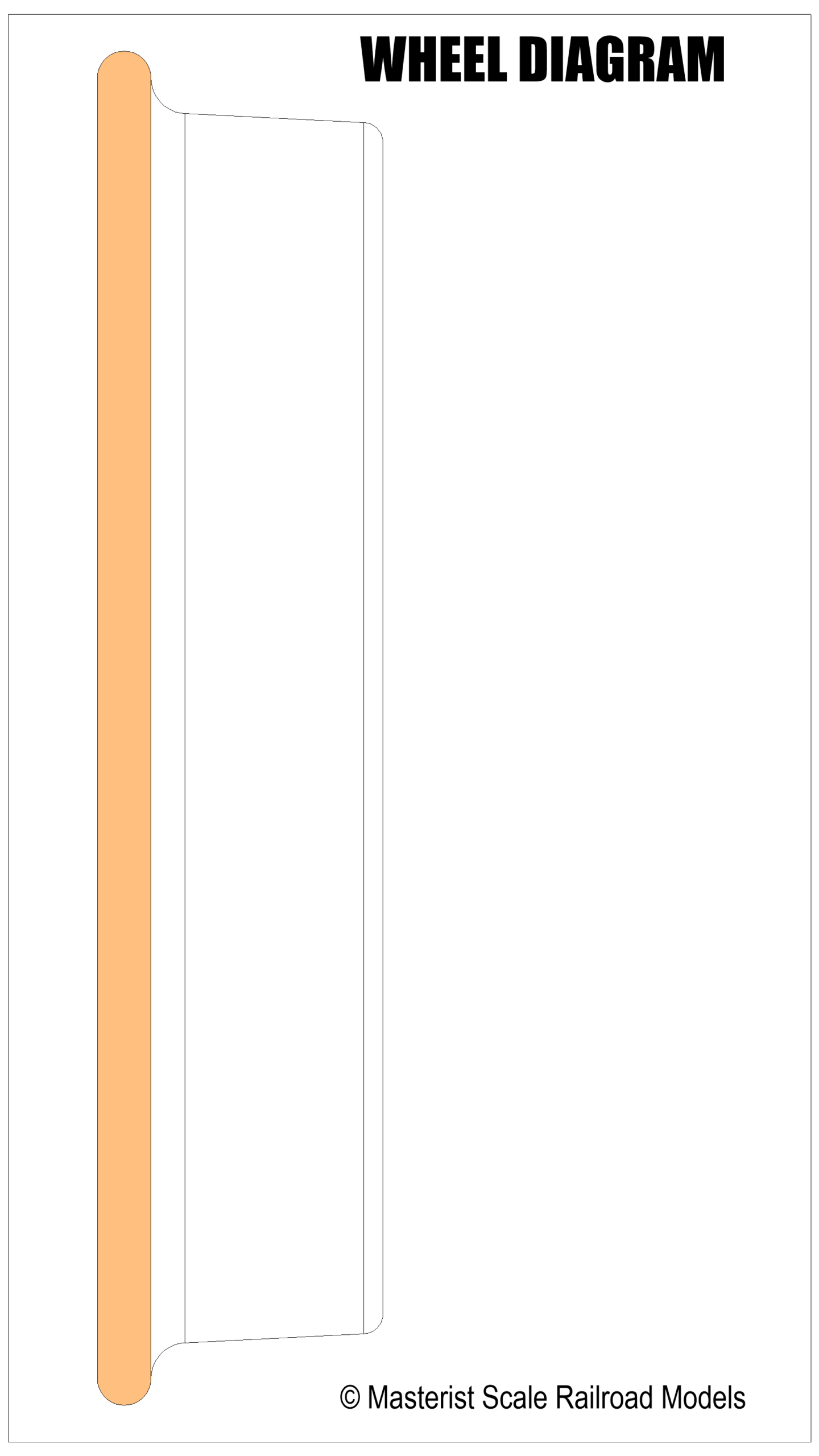

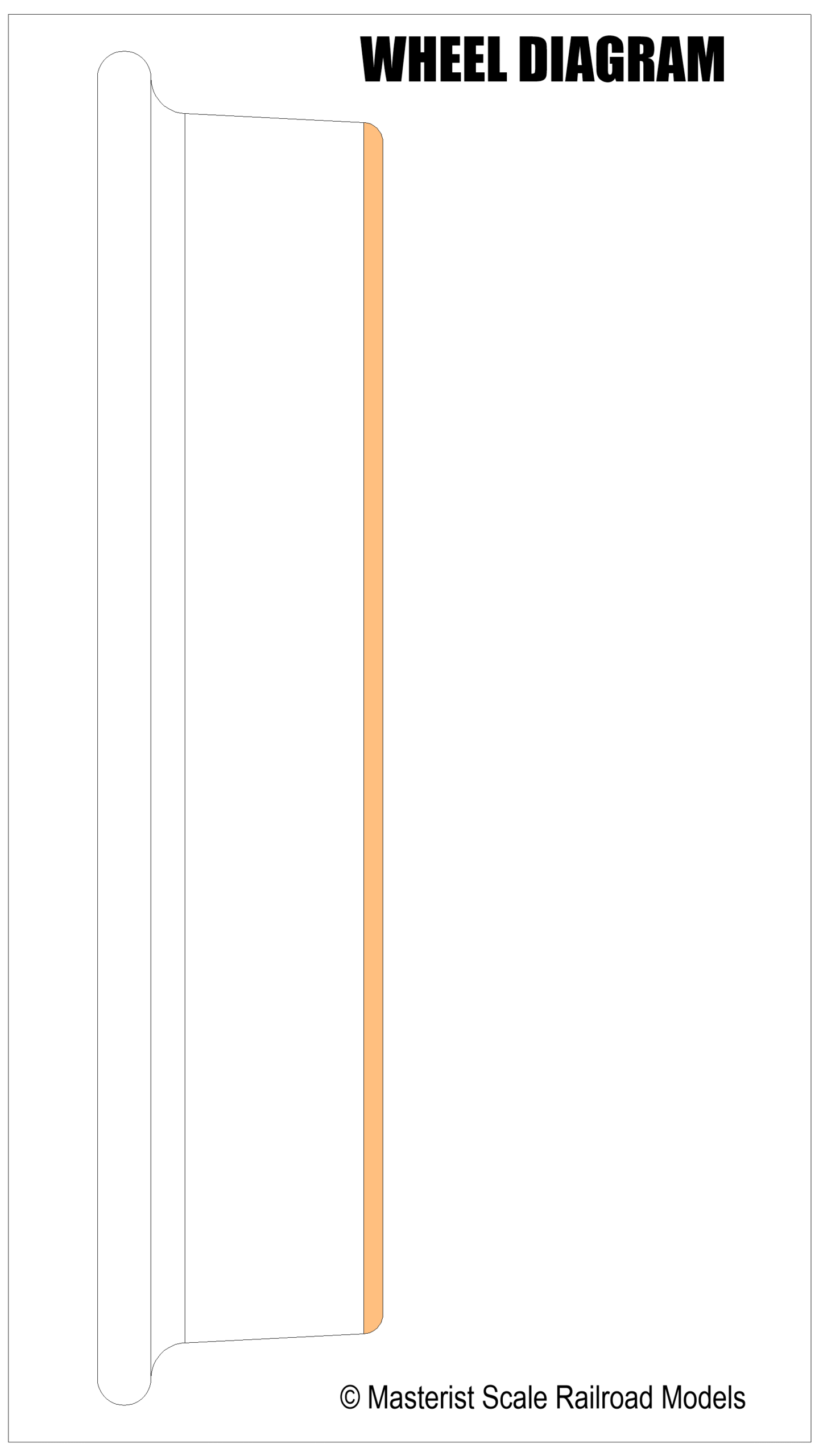

Located on the inner (back) side of the wheel. Commonly known as a last resort against derailment when speeding through the curve. When this happens – it results in a loud squeal, especially if wheelset is equipped with axle-mounted brake disks. It’s primary functions, however are:

- on the outer rail of a switch – guide the wheelset towards a guardrail to prevent jumping the FROG

- on the inner rail – take a fraction of the weight while traversing the FROG where there is a big gap between adjacent rails, sometimes reaching around a foot or 30cm in length on some long high-speed turnouts.

In railroad terminology it refers to the crossing assembly of inner rails of two different tracks at the point of divergence of a turnout.

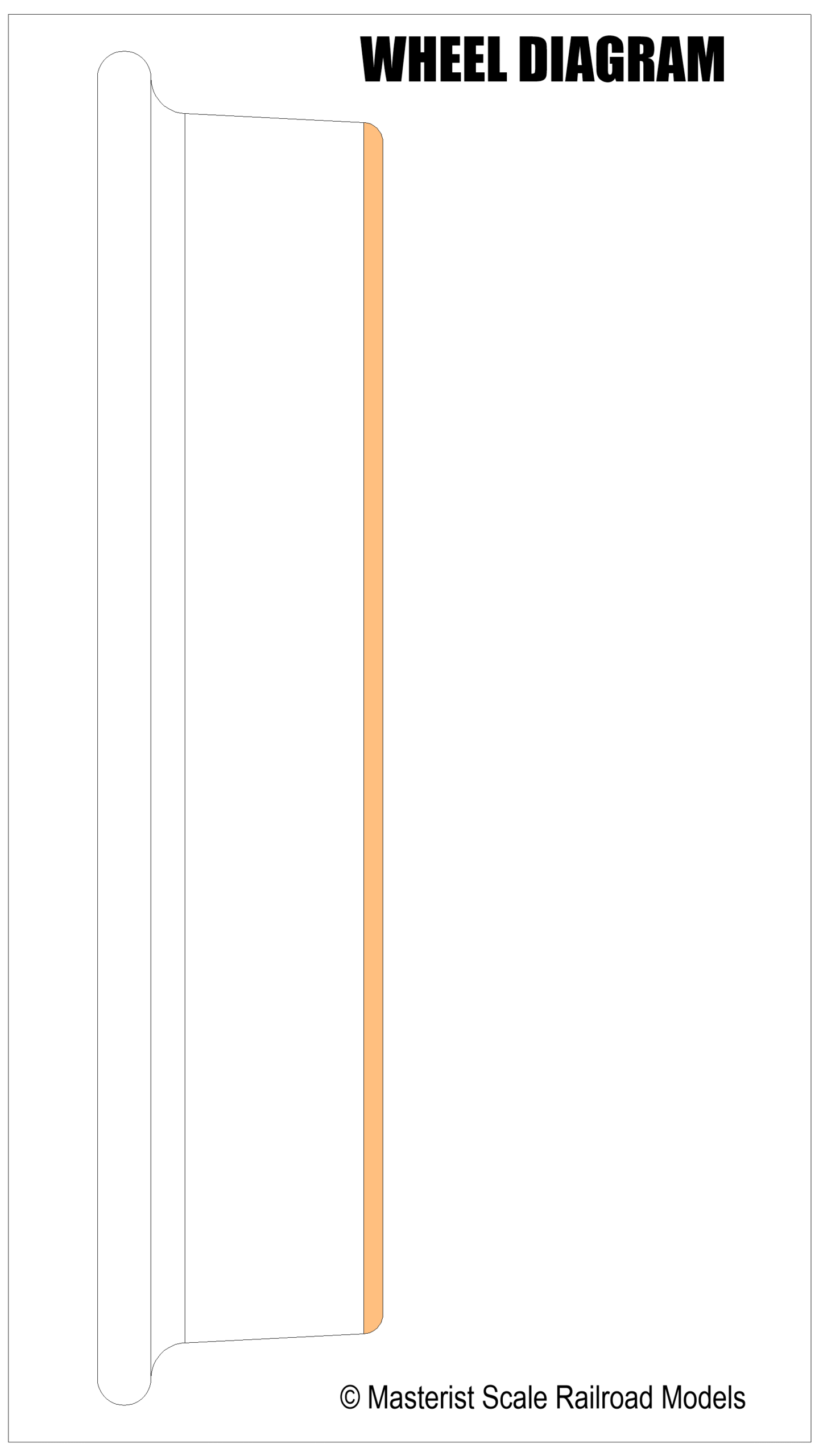

The curved surface at the front of the wheel, curving into the front wall. Just as the flange it is used in a very risky condition as a last resort, cooperating with the FLANGE to recenter the wheelset on the track from big off-center displacement.

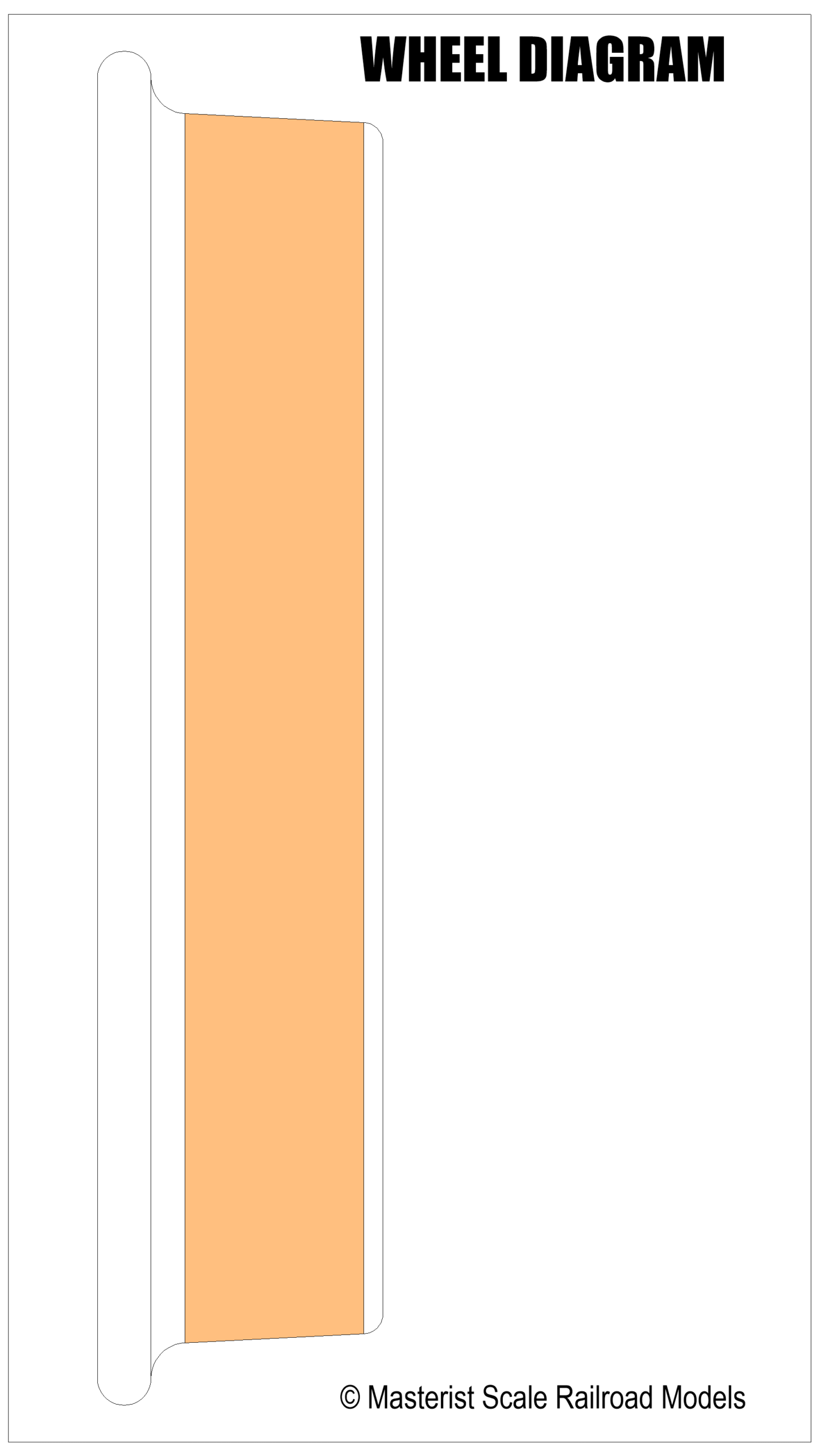

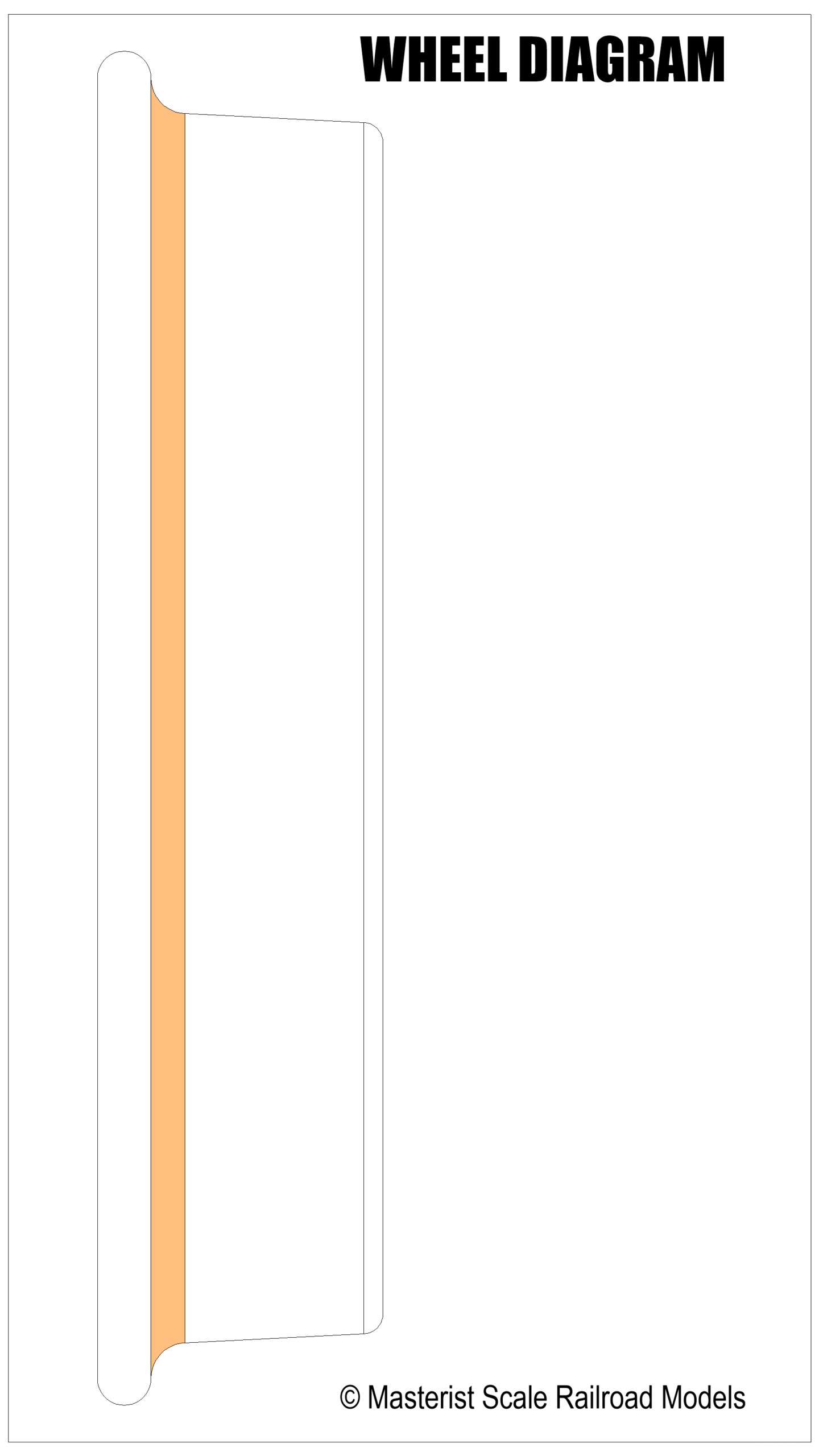

Curved area on the cross section of the wheel joining FLANGE and TREAD TAPER. Its common function is to recenter the wheelset on the track during curves at moderate speeds. When doing the job on tight curves at low speeds under a heavy load it is typical to hear metal popping sound.

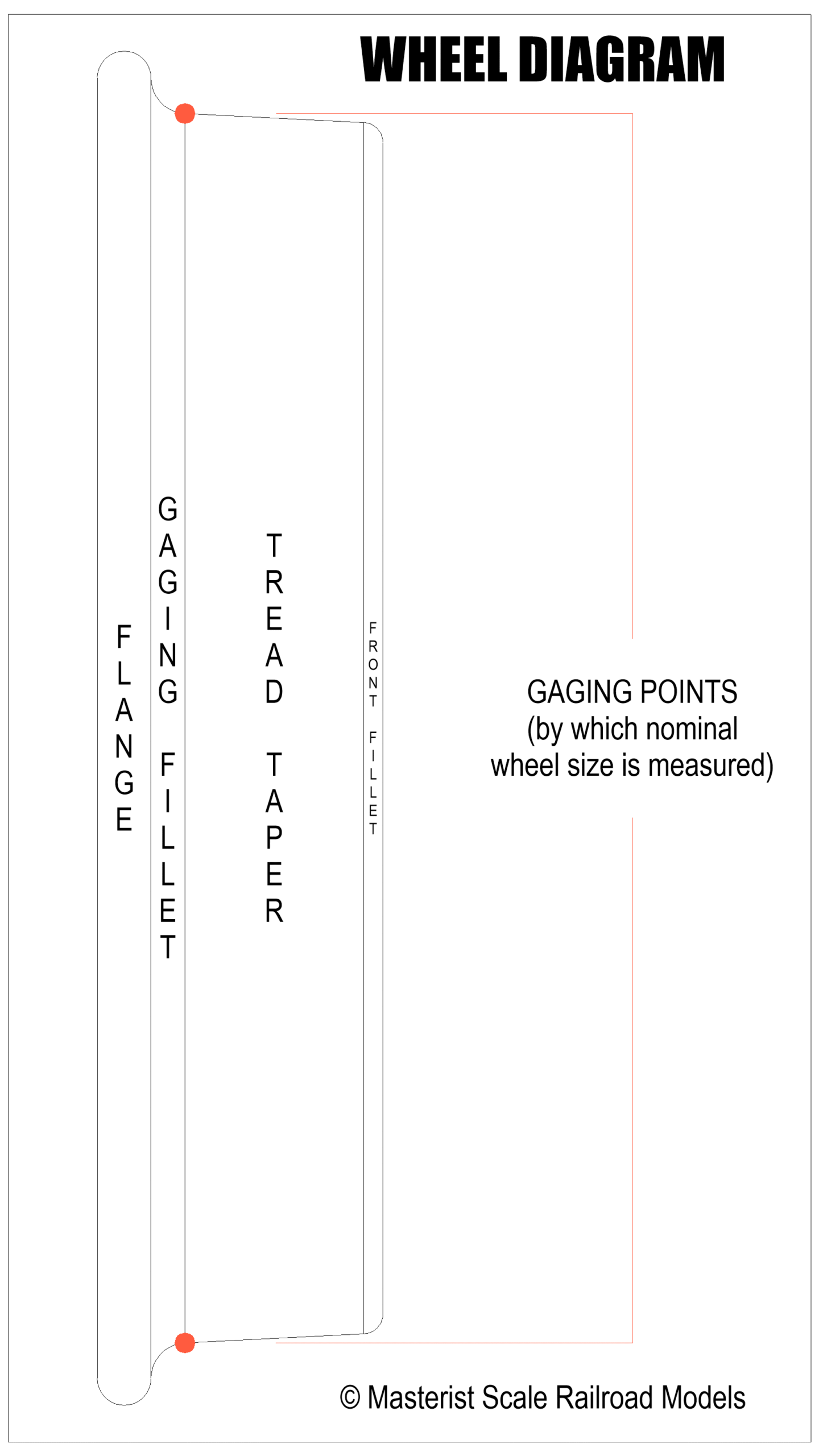

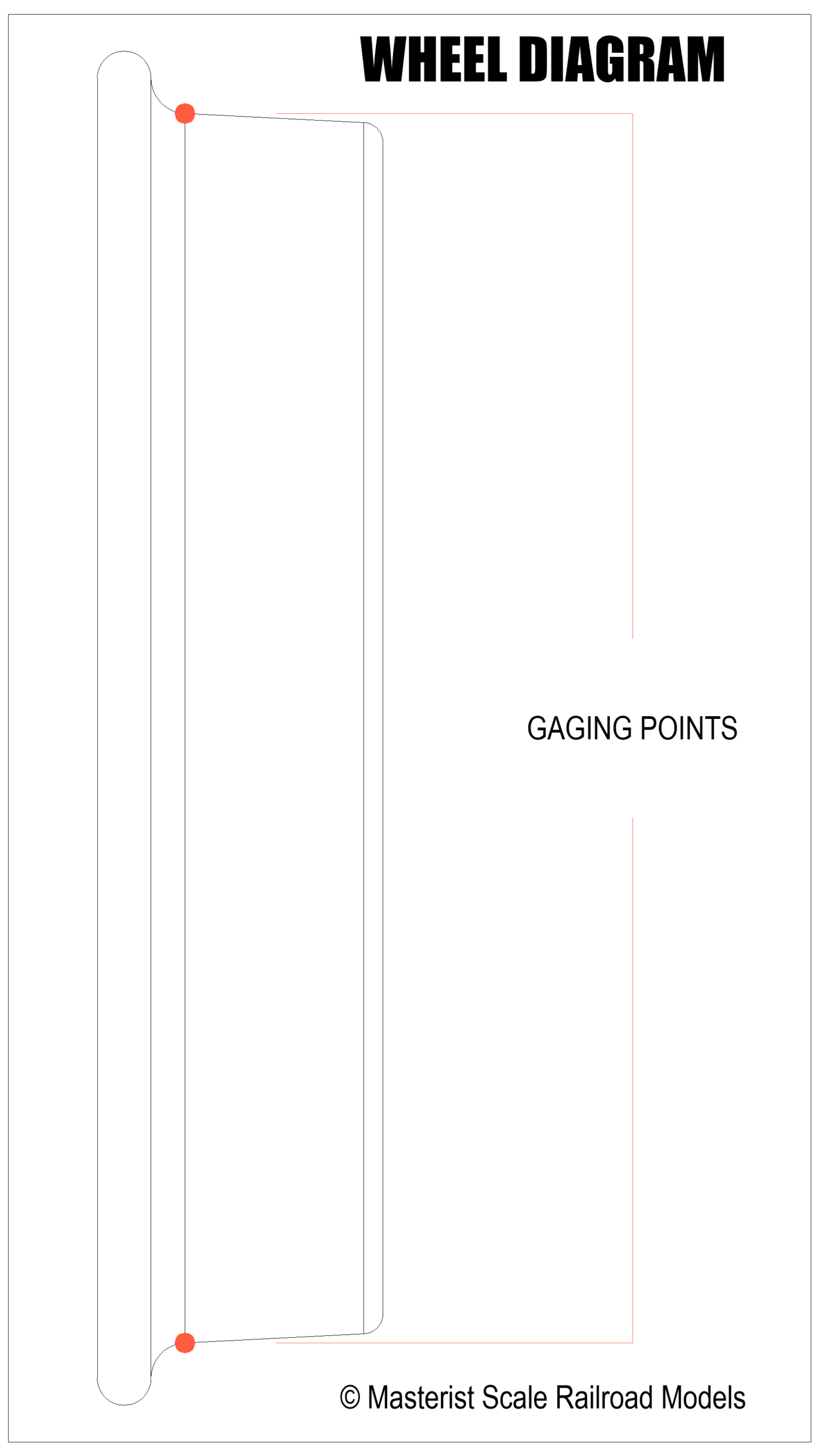

Vertex between GAGING FILLET and TREAD TAPER. It is the biggest diameter point that would contact the rail under normal circumstances. Nominal wheel diameters are measured by these points.

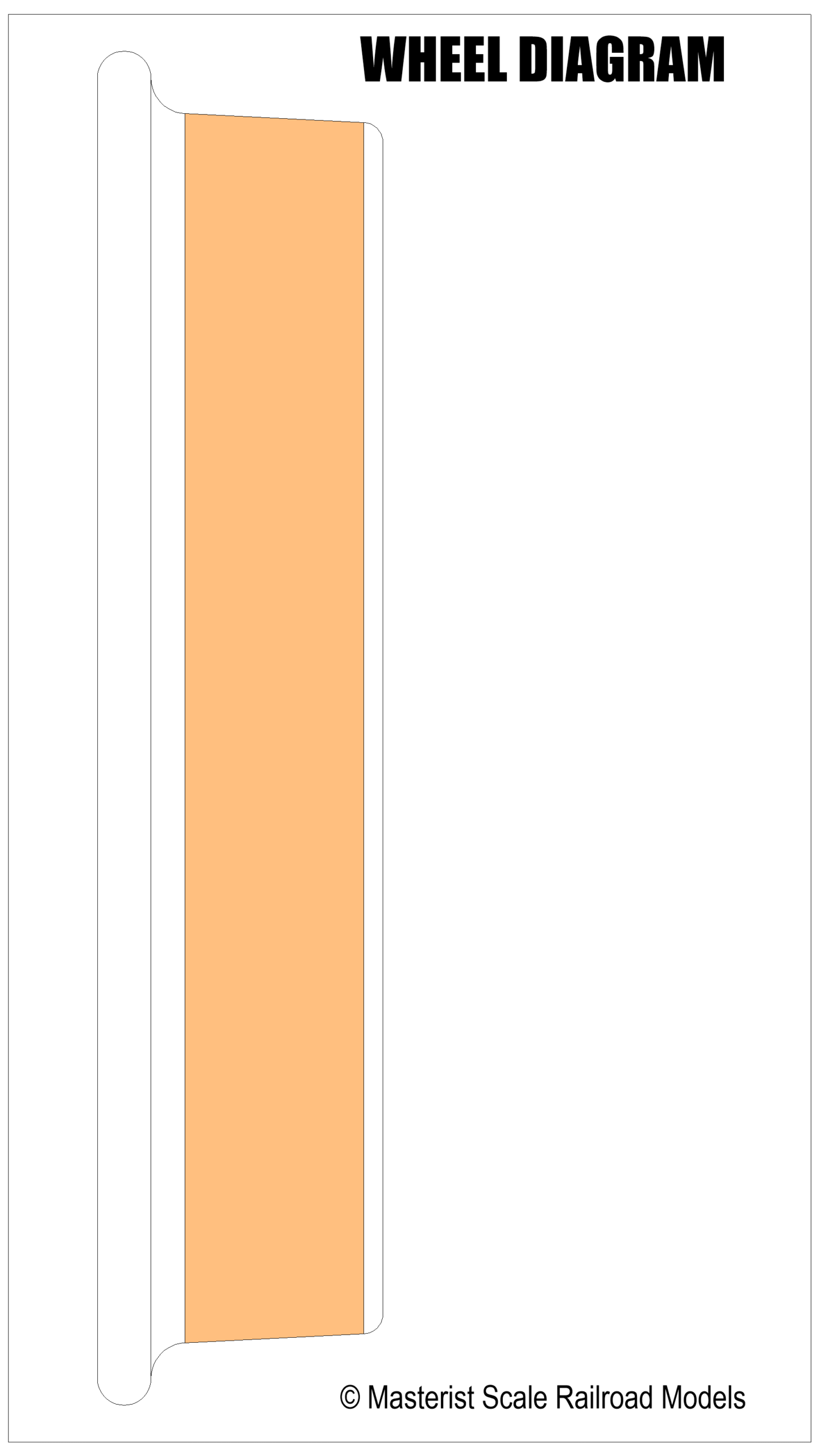

The conical surface of a wheel cross section intended to keep centering the wheelset at the center of the track during low impulses coming either from the very broad curves or lateral track irregularities.

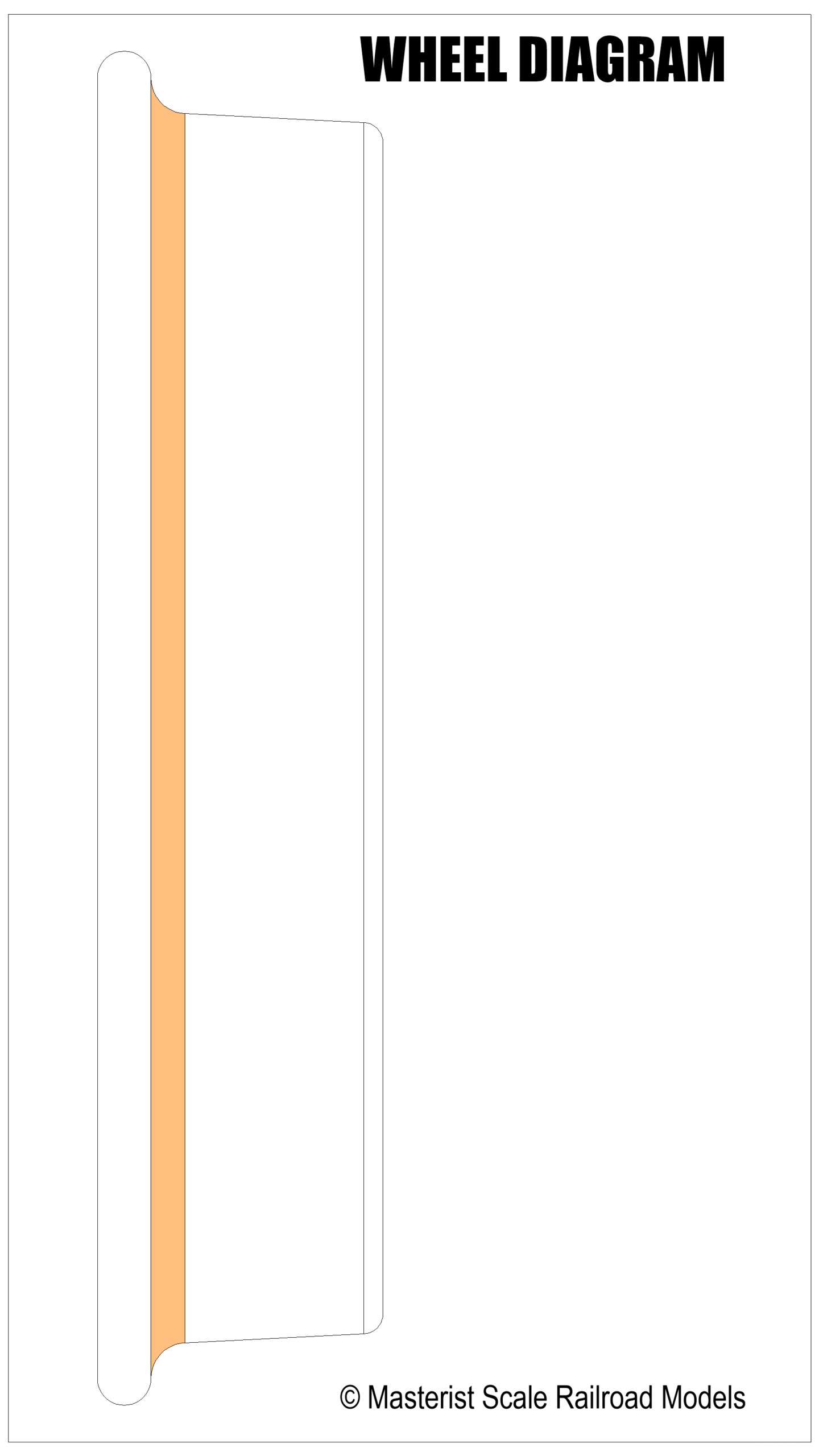

Located on the inner (back) side of the wheel. Commonly known as a last resort against derailment when speeding through the curve. When this happens – it results in a loud squeal, especially if wheelset is equipped with axle-mounted brake disks. It’s primary functions, however are:

- on the outer rail of a switch – guide the wheelset towards a guardrail to prevent jumping the FROG

- on the inner rail – take a fraction of the weight while traversing the FROG where there is a big gap between adjacent rails, sometimes reaching around a foot or 30cm in length on some long high-speed turnouts.

In railroad terminology it refers to the crossing assembly of inner rails of two different tracks at the point of divergence of a turnout.

The curved surface at the front of the wheel, curving into the front wall. Just as the flange it is used in a very risky condition as a last resort, cooperating with the FLANGE to recenter the wheelset on the track from big off-center displacement.

Curved area on the cross section of the wheel joining FLANGE and TREAD TAPER. Its common function is to recenter the wheelset on the track during curves at moderate speeds. When doing the job on tight curves at low speeds under a heavy load it is typical to hear metal popping sound.

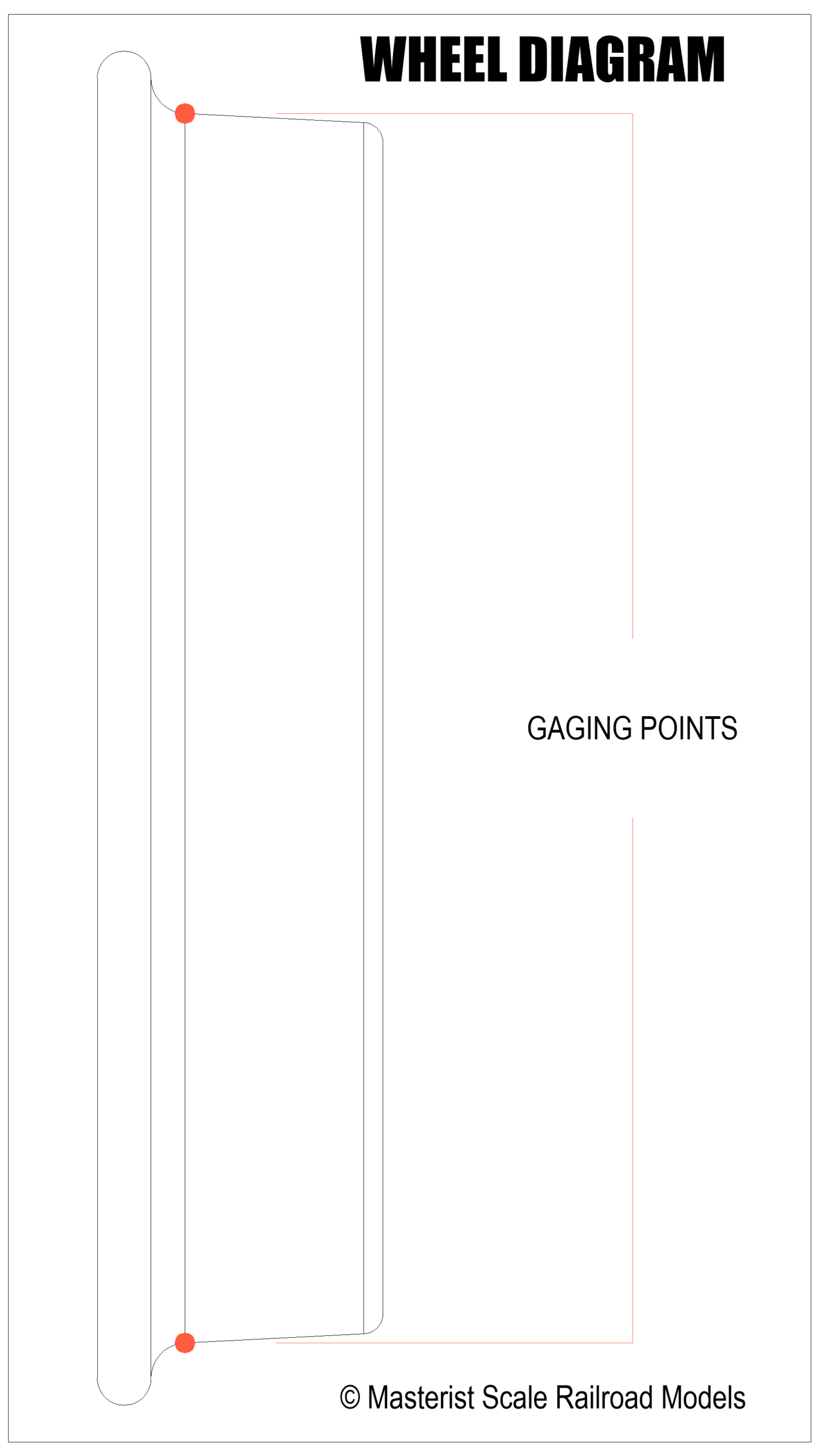

Vertex between GAGING FILLET and TREAD TAPER. It is the biggest diameter point that would contact the rail under normal circumstances. Nominal wheel diameters are measured by these points.

The conical surface of a wheel cross section intended to keep centering the wheelset at the center of the track during low impulses coming either from the very broad curves or lateral track irregularities.